PP/PE/PVC/PS Plastic Film Pelletizing / Granulation

No need for water washing, directly feed and granulate.

Types of films that can be used for granulation include:

- PE film category: including agricultural greenhouse film, mulch film, and daily life product packaging bags.

- PP film category: including food packaging bags, cling film, and clothing packaging bags.

- PVC film category: industrial packaging bags and films.

- PS film category: food packaging, electronic and electrical packaging, stationery packaging, etc.

Product Videos

Film material types

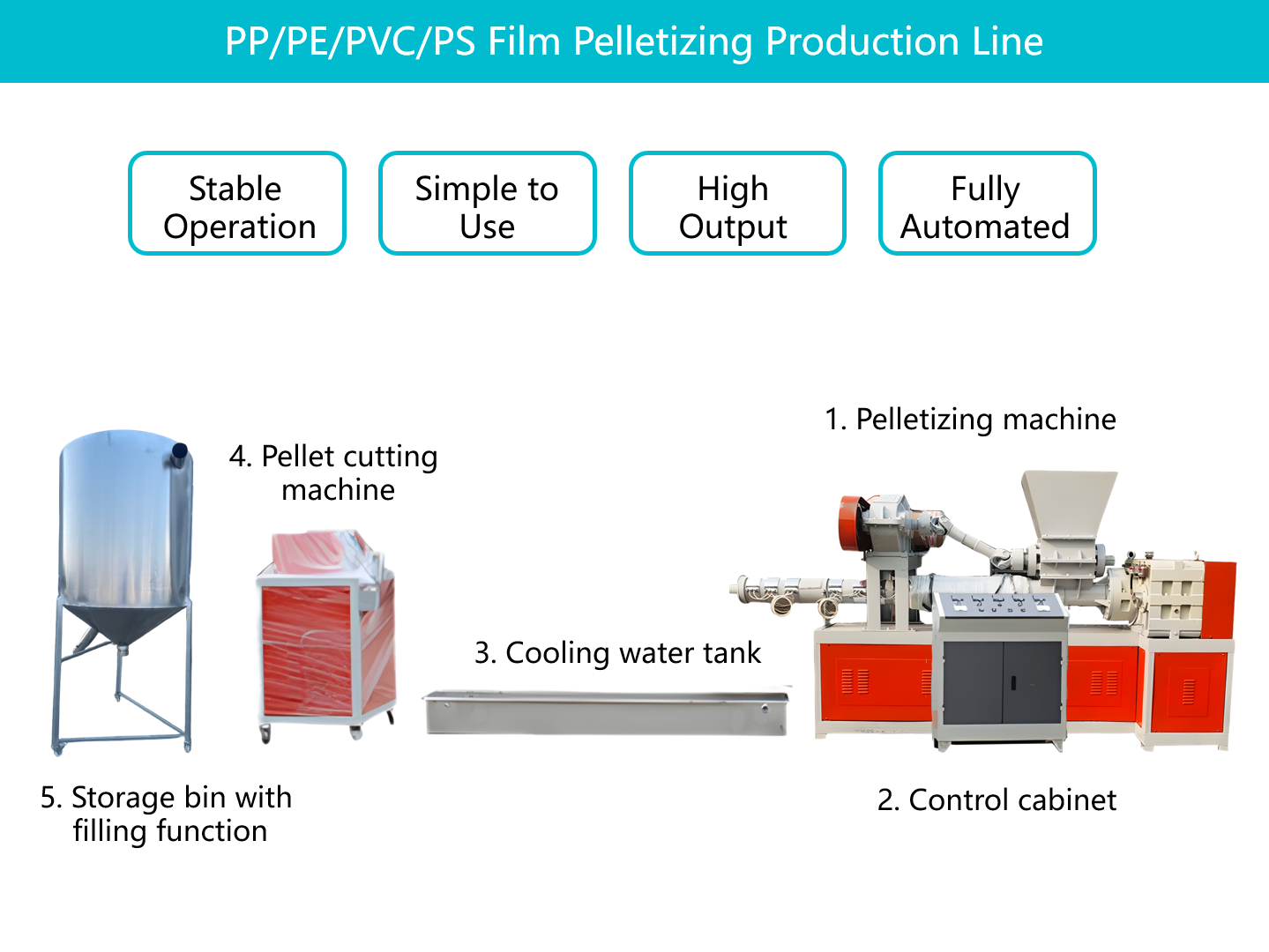

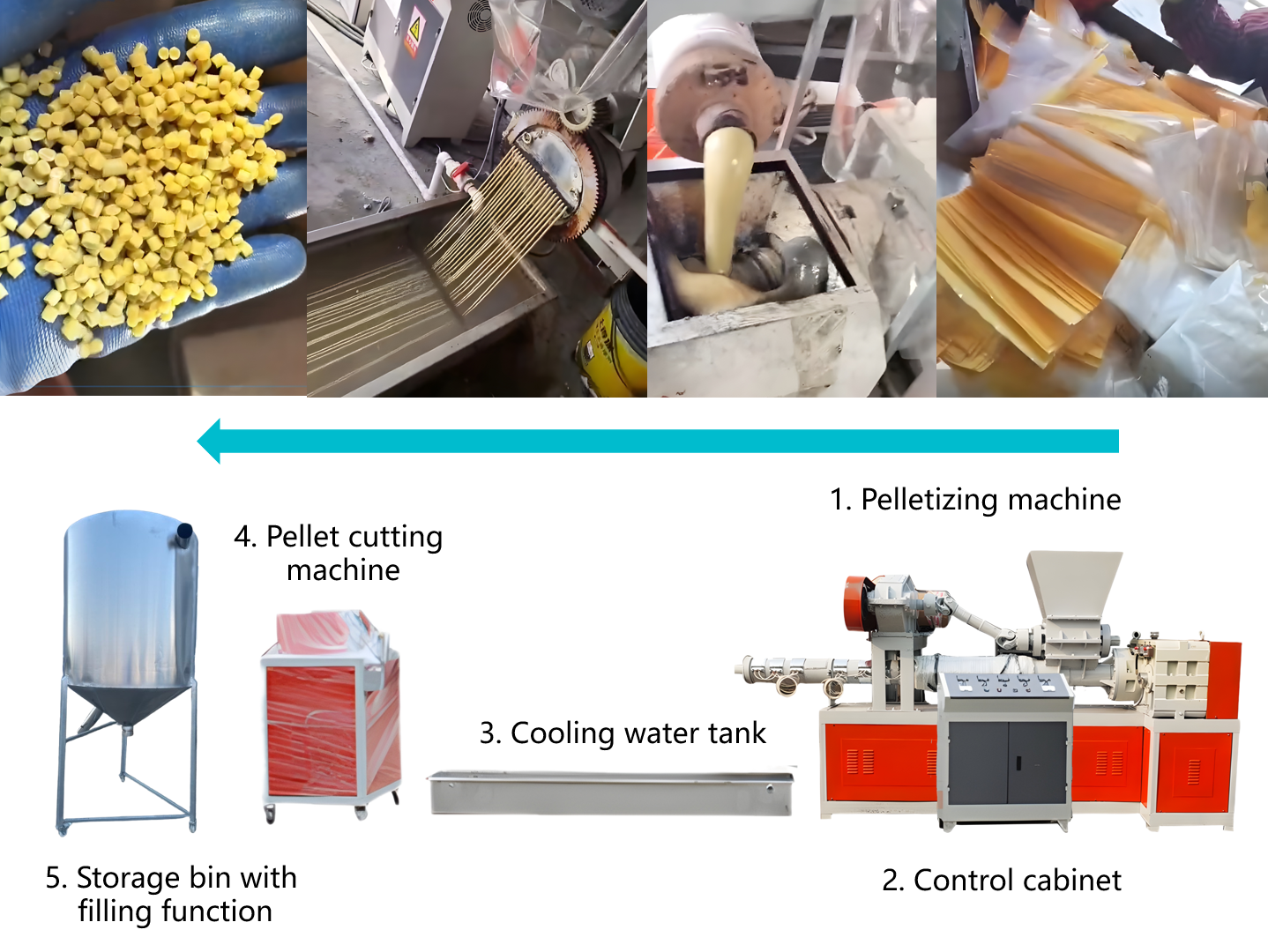

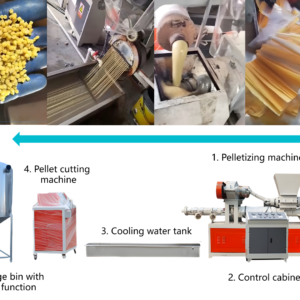

Product composition

Includes a complete set of film pelletizing/granulation production lines, with a total of 5 product components:

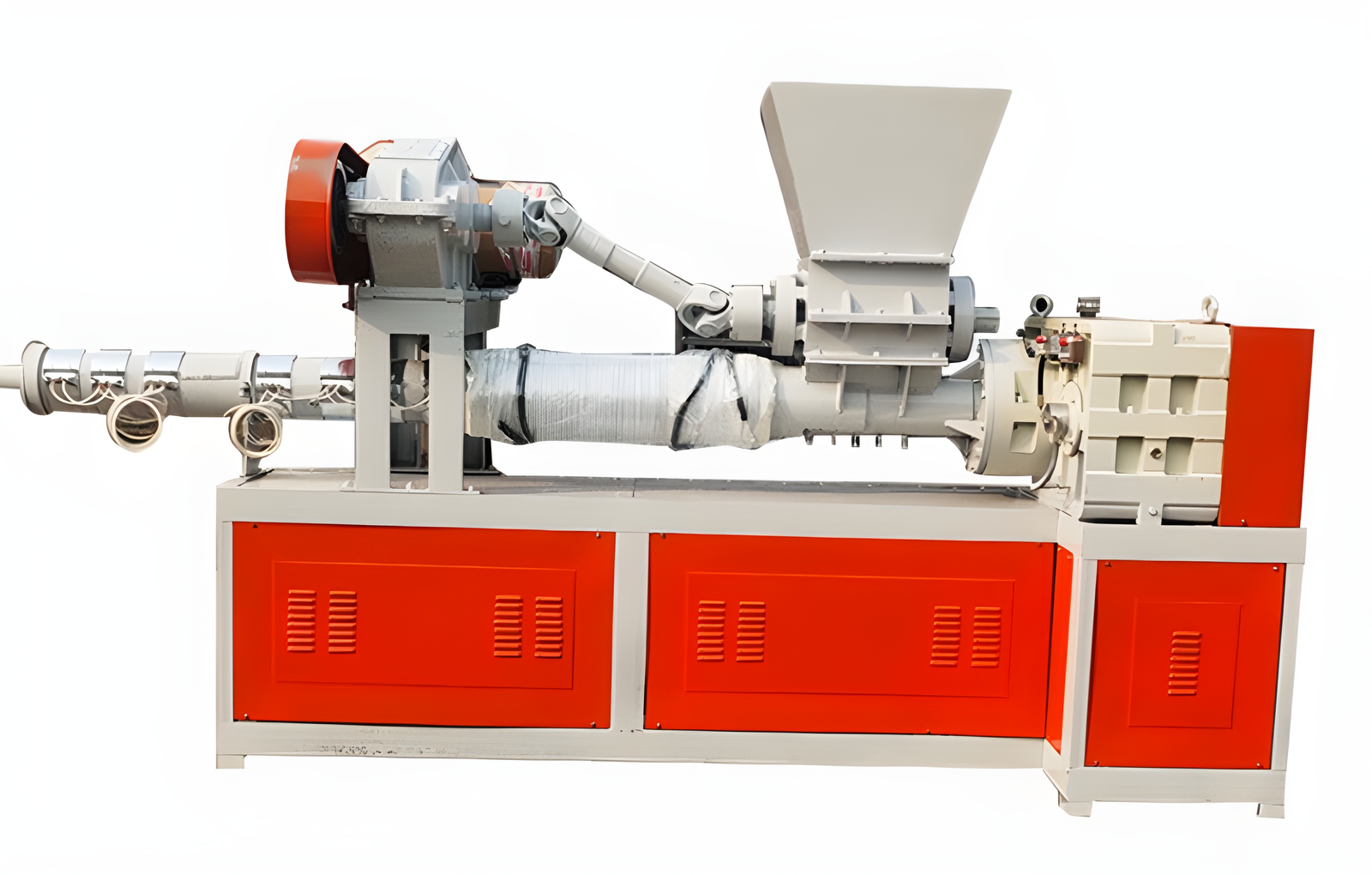

1. Pelletizing main machine with forced feeder, function: feeding crushing and heating melting;

2. Stainless steel cooling water tank: cooling plasticized plastic strips;

3. Roller frequency conversion cutting machine: pellet cutting;

4. Stainless steel storage silo: storage granules with filling function;

5. Control cabinet: power distribution and control of all machines;

Key attributes, Industry-specific attributes

| Output, kg/h | 200-300 |

| Plastic Processed | PP, PE, PVC, PS Plastic Film, Woven Bags, etc |

| Core Components | Electric Motor/Diesel Engine, Gearbox |

Features:

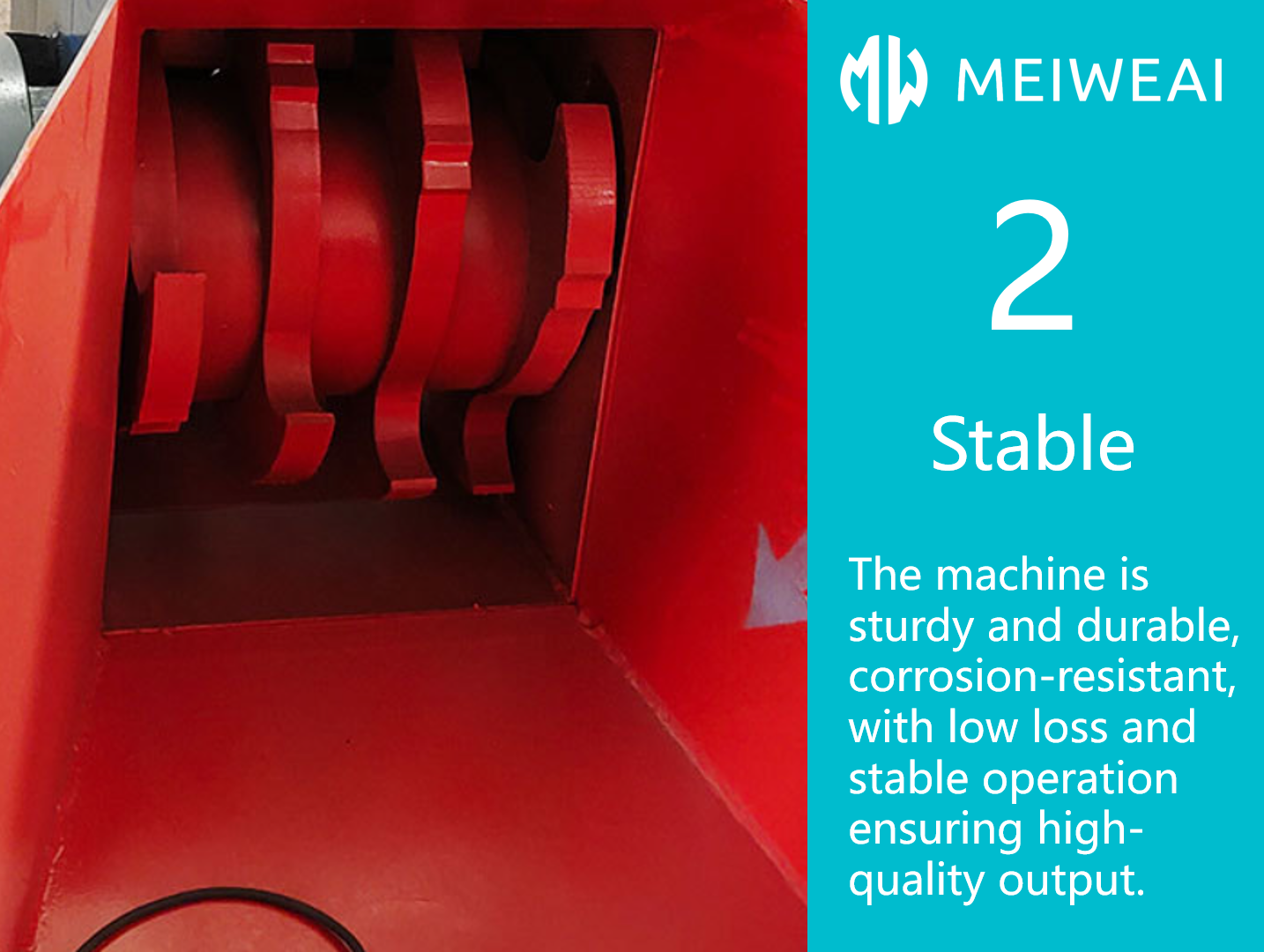

- Hardened tooth surface reducer, wear-resistant and durable for long-term use, stable.

- Equipped with a forced feeder for efficient feeding.

- High-power pure copper motor.

- Equipped with a die head motor for automated screen change, enabling rapid screen change without shutdown.

- Complete set of electromagnetic heating.

- Digital display temperature control in the power distribution cabinet.

- Stainless steel cooling water tank.

- Frequency conversion pelletizer with hob knives, efficient and with good pelletizing effect.

- 1 ton stainless steel silo can store and complete bag filling.

Specification:

| Model, FILM-PL- | 135 | 150 | 165 |

| Output, KG/H | 150~200 | 225~250 | 275~300 |

| Total Power, KW | 110 | 150 | 190 |

| Screw Diameter, mm | 135 | 150 | 165 |

| Overall Dimensions, L*W*H, M | 5*2.3*1.5 | 5*2.3*1.5 | 6*2.3*1.6 |

| Reducer | Model 225 Hardened tooth surface | Model 250 Hardened tooth surface | Model 250 Hardened tooth surface |

| Feeder | Forced feeder equipped with a reducer | Forced feeder equipped with a reducer | Forced feeder equipped with a reducer |

| Pelletizing Machine Motor Power, KW | 52.5 | 55 | 75 |

| Feeder Motor Power, KW | 7.5 | 7.5 | 7.5 |

| Heater | 40KW electromagnetic heating, with electromagnetic power control cabinet. | 60KW electromagnetic heating, with electromagnetic power control cabinet. | 80KW electromagnetic heating, with electromagnetic power control cabinet. |

| Pelletizing Auxiliary Machine | / | Model 150 equiped with 200 Hard Tooth Surface Reducer 22KW motor, 2.2KW die head motor, Electric gear die head. |

Model 165 equiped with 200 Hard Tooth Surface Reducer 18.5KW motor, 2.2KW die head motor, Electric gear die head. |

| Power cabinet | The main machine starts with variable frequency. | The main machine starts with variable frequency. | The main machine starts with variable frequency. |

| Cooling Water Tank | 3-meter stainless steel water tank. | 3-meter stainless steel water tank. | 3-meter stainless steel water tank. |

| Pellet Cutting Machine Model | 180 type rotary cutter variable frequency pelletizer. | 180 type rotary cutter variable frequency pelletizer. | 180 type rotary cutter variable frequency pelletizer. |

| Storage and bagging Machine | 1 ton stainless steel silo with bag filling function; | 1 ton stainless steel silo with bag filling function; | 1 ton stainless steel silo with bag filling function; |

| Approx.Net Weight, kg | 4000 | 4000 | 5000 |

*Disclaimer for product parameters: The product model parameters are for reference only. The final actual order placed shall prevail.

Other attributes

| Brand Name | Meiweai |

| Manufacturer Name | Hangzhou Meiweai Machiery Technology Co., Ltd. |

| Condition | New |

| Warranty of core components | 1 Year |

| Place of Origin | Zhejiang, China |

After-sales service

| After-sales service | Remote video technical support |

| Warranty of core components | 1 Year |

Packaging and delivery

| Packaging Details | Wooden Case |

| Port | Ningbo, Qingdao |

Supply Ability

| Supply Ability | 20 Sets per Month |

Why Choose us

Product advantages

Product details

Reviews

There are no reviews yet.